welding hardness test|how to check weld hardness : convenience store Discover the welding hardness test's role in ensuring weld quality, structural integrity, and process optimization. Learn about machinery, preparatory steps, and test outcomes for enhanced welding performance. Resultado da NEW - Watch a video recording of the game. Told through a therapy session, Milfy City is one heck of an interesting visual novel of a video game. With .

{plog:ftitle_list}

reviews. custom lists. Ch: 106+. Kakao toon. 2022 - ? 4.143 out of 5 from 292 votes. Rank #1,403. L.A.G, an unknown space where humans use abilities or skills through .

why is hardness testing important

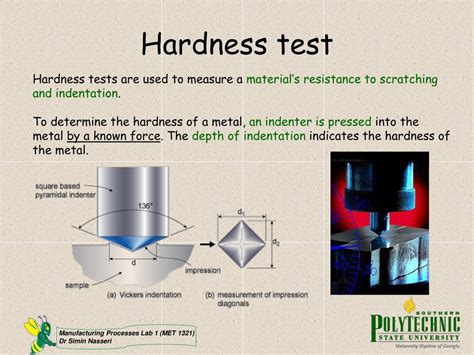

Hardness testing assesses a material’s ability to resist permanent deformation at its surface by applying pressure with a harder material. It finds applications across various industries for comparing and selecting materials, as well as ensuring quality control in manufacturing or .Discover the welding hardness test's role in ensuring weld quality, structural integrity, and process optimization. Learn about machinery, preparatory steps, and test outcomes for enhanced welding performance. Metallurgical Supply Company (METSUCO) has been a leading supplier of hardness testing supplies for welding and welding joints for over 30 years. We serve not only industries such as oil and gas, aerospace, . There are many different types of destructive testing, but some of the most common are fracture mechanics testing, impact testing, and hardness testing. Fracture mechanics testing is used to determine the strength and .

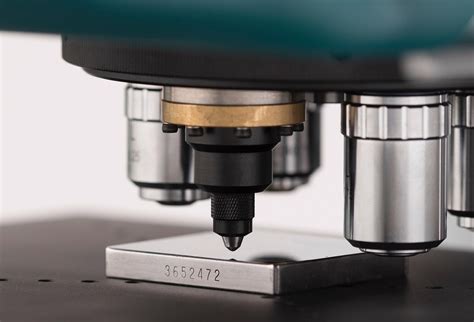

A Vickers hardness tester. The Vickers hardness test was developed in 1921 by Robert L. Smith and George E. Sandland at Vickers Ltd as an alternative to the Brinell method to measure the hardness of materials. [1] The Vickers test is often easier to use than other hardness tests since the required calculations are independent of the size of the indenter, and the indenter . Only QW-290 for temper bead welding defines hardness testing. Hardness testing of carbon steels are not defined in most construction Codes; it is addressed in API-582 and various NACE publications as a means to mitigate stress corrosion cracking. ASME Codes place the responsibility for corrosion related design on the Owner/Engineer. Low hardness and high hardness areas can be obtained due to a number of welding factors; such as, inadequate preheat both too low and highly excessive especially when using flame methods, too low or too high PWHT due to improper T/C placement, furnace hot and cold spots Slow too slow a cooling rate from the normalizing temp, etc.

Figure 5, Typical results from hardness test of a groove weld. Figure 6 shows the detailed pattern for measuring the hardness of a fillet weld geometry. Figure 6, Typical pattern of hardness test of fillet weld. In conclusion Table 1 shows the difference between the hardness test methods discussed and their application, if any, to weldsThe welding variables are recorded during welding of the test piece and hardness testing is mandatory, the hardness of the test weld HAZ to be less than 248Hv10, that of the weld metal less than an average of 200HBW. Hardness testing surveys are as described in NACE MR0103. In addition to the ASME IX requirements, SP0472 requires butt welds and . Both paragraphs use the term 'as welded'. A PQR test weld is not an 'as welded' pressure vessel for example. Of course, the applicable clause for hardness testing, 7.3, only deals with PQR hardness testing and then goes on to completely omit any controls on applying qualification hardness to a change in steel chemistry or the like.Welding Hardness Test Machine. The welding hardness test often employs a portable hardness tester, specifically designed for both on-site and laboratory use. One of the prominent types is the Rockwell hardness tester, featuring a hardened steel ball or diamond cone indenter, an adjustable load mechanism, and a scale for measuring indentation depth.

In Rockwell hardness testing, HRA, HRB, and HRC represent three different scales: Scale A, Scale B, and Scale C. The Rockwell test is a common indentation hardness test. All three scales begin with an initial pressure of 98.07N (10kgf), and the hardness value is calculated based on the depth of indentation. Hardness testing of weld overlay procedure test as per ISO 15156-2. Hardness testing shall be carried out by the Vickers 10-kg or 5 kg method in accordance with ISO 6507-1 I ASTM E 92. Hardness testing shall additionally be carried out by the Rockwell method in accordance with ISO 6508-1 I ASTM E 18. A hardness test is used to determine the hardness of weld metal. By careful testing of a welded joint, the hard areas can be isolated and the extent of the effect of the welding heat on the properties of the base metal determined. Hardness Testing Equipment. File Test: The simplest method for determining comparative hardness is the file test.

The document provides instructions for conducting hardness testing of welds. It specifies that testing should use the Vickers method with a 5 kg or 10 kg load in accordance with ASTM E92. Other hardness testing methods are not acceptable. When hardness values are specified using a different scale than Vickers, the Vickers equivalent must be used. Hardness testing is . Vickers (HV) hardness test, sometimes called microhardness test only use one type of indenter of pyramid-shaped diamond with different load. Depending on the standards used, HV 30, HV 10, & HV 5 are allowed for tests. HV 30 is used for bulk metal, HV 10 is for HAZ, and HV 5 is used for low arc energy welds (<2.5 kJ/mm) which may have a very .

Find Weld Hardness Testing stock images in HD and millions of other royalty-free stock photos, illustrations and vectors in the Shutterstock collection. Thousands of new, high-quality pictures added every day.

Hardness of the Welded metal is very important property of the metal especially consideration of that during and after the welding.This video cover basic abo.

Study with Quizlet and memorize flashcards containing terms like 1. True or False? NDE involves testing that does not damage the weld., 2. True or False? Destructive testing is done to determine the physical properties of a weld., 3. Visual inspection does not reveal which of the following? A. size of the weld B. internal defects C. contour of the weld D. spatter and more.

My Client intend to have Production Weld Hardness test for our "NACE" categorize material. We are in a Gas Plant processing (AGRU & SRU). In NACE MR0175. The weld deposite value for WPS/PQR is 250 HV. However HV can not be used for production weld, since it needs to be destructive test. While portable hardness test is usually brinell.Microstructure Analysis - Preparation: Weld - Hardness Test. In a weld process test, the sample is also processed metallographically. In the zones hardness tests are carried out at a defined position to determine an increase .As illustrated in Fig.3(b) two diagonals, d 1 and d 2, are measured, averaged and the surface area calculated then divided into the load applied.As with the Brinell test the diagonal measurement is converted to a hardness figure by referring to a set of tables. The hardness may be reported as Vickers Hardness number (VHN), Diamond Pyramid Number (DPN) or, most commonly, Hv . welding conform to AWS D1.1, API 1104, or ASME Section IX. • Auditors may review Procedure Qualification Record(s) PQR(s) that support the Welding Procedure Specification . o Hardness Testing o Fracture Toughness Test (if required) o Radiographic or other NDE report

After PWHT must be need to Checking metals hardness capability. So let's see the reading. Note: it was just for practices.

welding hardness test pdf

Vickers Hardness-test. Here the indenter is a square based diamond pyramid with opposite faces forming an angle of 136 degrees.Accepted loads are 5, 10, 30, 50 kg but smaller an larger loads can be used when necessary.. The diagonals of the impression have to be precisely measured with a microscope, and the Vickers hardness result is looked up in tables. . The Hardness . 6. General types of hardness testing... Current practice in USA divides hardness testing into two categories: Macrohardness: Refers to testing with applied loads on the indenter of more than 1 kg and material being tested are tools, dies and sheet material in the heavier gages(in large scale) Microhardness: Refers to testing with applied loads are 1 kg or .

How to control Weld / HAZ Hardness levels Example of a simple Fillet Welded Bar to Plate PQR/WQ Test Piece sent into the Laboratory for Qualification, what can go wrong? Why is Preheat a critical .The testing facility at our company stays well-equipped with common coupons necessary for weld qualification testing. Our team of CWIs (certified welding inspectors) evaluates proper techniques according to appropriate standards and codes. Here you can join over 40,000 Welding Professionals & enthusiasts from around the world discussing all things related to Welding. You are currently viewing as a guest which gives you limited access to view discussions . I've never been around anyone portable testing aluminum for hardness but I 'spect it could be done with a sample and the .When testing the hardness of a welding point, multi-point measurements will be made at a certain distance from the edge of the sample or the top of the welding point. After obtaining the multi-point indentation, the hardness value can be measured by continuous measurement and a curve graph can be obtained.

In TMCP steels, a limit is often placed on heat input to avoid undue softening in the weld region, (see Is there a restriction on the heat input that can be used for the welding of TMCP (Thermo-Mechanically Controlled Processed) steels - if so, why?) Reference. BS EN 1011-2:2001 Welding - Recommendations for welding of metallic materials.

how to test for soft tissue damage

WEB24 de mar. de 2023 · John Wick: Chapter 4 feels like an unpolished workprint, a thrilling, violent, slam-bang climax that never stops climaxing. . The result makes "Chapter 4" feel like an unpolished workprint, a .

welding hardness test|how to check weld hardness